5 Layer Stretch Film Machine/ PE Stretch Film Making Machine Quality Assured

| Delivery Time: | 80 Days |

|---|

| Packaging: | 1) Packed fully with EPE foam, blanketry and stretch film.2) Wire netting fastened at the bottom of the container. |

|---|---|

| Brand: | XHD |

| Place of Origin: | Guangdong, China (Mainland) |

Basic Info

Model No.: XHD-L65/90/65*1850

Product Description

Dedicated in stretch film machine for More Than Ten Years.

----- Because the focus, so professional

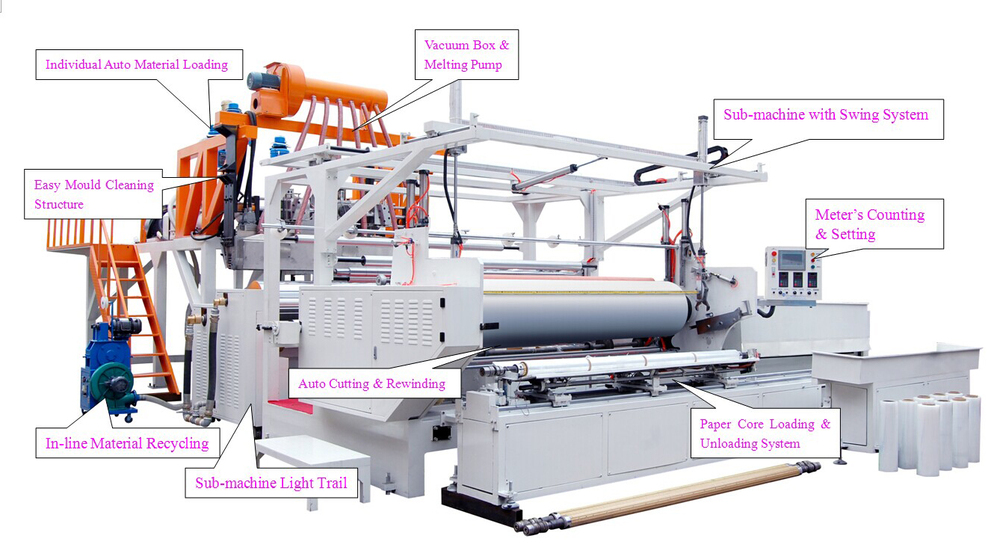

5 Layer Stretch Film Machine/ Pe Stretch Film Making Machine

Three layers co-extrusion Stretch film machine for fully automatic

Three layers co-extrusion stretch film machine for fully automatic mainly use LLDPE,LDPE or recycled LLDPE material to produce one side sticky or 2 sides sticky grass film, stretch film,cling film,cast stretch film etc.The width from 20mm to 2000mm, single layer to 2 layers, 3 layers, 5layers and so on.

This Unit is based on our long time manufacturing experience and customer's actual operate, Combine with Italy and Amercian high-tech to produce high plasticity, easy to operate, long life and power saving machine.This machine is fit for making stretch film, cling film and protecting film.

Detail Technical Parameter of Three layers co-extrusion stretch film machine for fully automatic

| Model | XHD-LΦ65/90/65X1850 |

| Layers | 3 layers |

| Screw Diameter | Φ65/90/65mm |

| Screw L/D | 1:30mm |

| Screw speed | 20-150rpm |

| Width | 1500mm/3*500mm |

| Total Power | 150KW |

| Thickness | 0.012-0.05mm |

| Capacity | 150~230kg/h |

| Layer Structure | ABC/ABCBA |

| Total Weight | 13T |

| Dimension | (L)12500*(W)4500*(H)4500 |

Optional system of High Stretching PE Film Production Line / 5 Layer PE Film Extrusion Machine Spare Part

| No | Item | Functions | Pictures | ||||||

| 1 | Vaccum Box | To suck the air and dust from the die to make sure the film cling on the cooling roller and transparent |  | ||||||

| 2 | Melting Gear Pump | This is to increase or decrease the pressure inside of screw to make the pressure is stable. So the film can be even and thickness uniformity. | |||||||

| 3 | Paper Core Changing | full automatic paper scroll loading & unloading system; automatic air shaft inflating system; No need to put adhensive tape on paper scroll (5.7 inch touch screen control) |  | ||||||

| 4 | Auto Filter Change | to change the filter automatically |  | ||||||

| 5 | Corona System | to lock the edge of film by static type |  | ||||||

| 6 | In-line Material Recycling | to recycle the wast material automatically |  | ||||||

The Advantages of Casting Way than Blown Way

1> Cooling time is short, so that the thickness and transparency of the film is better than blown way;

2>Gap of different rolls is small, so the evenness of film is better than blown way;

3> As we all known, the capacity is bigger than we used blown way.

Characters

| Items | Usage |

| 1>Auto Cutting & Rewinding | To cut and rewind the stretch film automatically |

| 2>Japan Mitsubishi PLC with Meter Counting & Setting | The meters of stretch film machine can be shown clearly |

| 3>Sub-machine Light Trail | Move the sub-machine automatically for easy T-die Cleaning |

| 4>The Sub-machine with Swing System | Make the stretch film more even and solid through swing the sub-machine |

| 5>Individual Material Auto-loader | Auto Material Loading |

| 6>In-line Material Recycling machine | Extra Material Recycling |

| 7>1st Cooling Roller: φ600mm;2nd cooling roller size:φ370MM | Make sure the good cooling, adopt the imported technology |

Finished Products of High Stretching PE Film Production Line / 5 Layer PE Film Extrusion Machine

It is a very good kind of packaging material mostly used in the industrial field,port pallet packaging;

building material packaging; hardware packaging etc. It enjoys the following advantages:

1) Good tensile strength

2) Superior anti-pricking ability

3) High transparency

4) Good ductility and anti-impact strength

5) Stable sticky sides etc

Finished Products of cling film machine

It is for all kinds of food package. Fruit, Dishes, Cooked Food and etc. It enjoys the following advantages:

1) Food Grade Cling Film

2) Great for edible items

3) Safe and non toxic

4) High strength and durability

5) Many size available

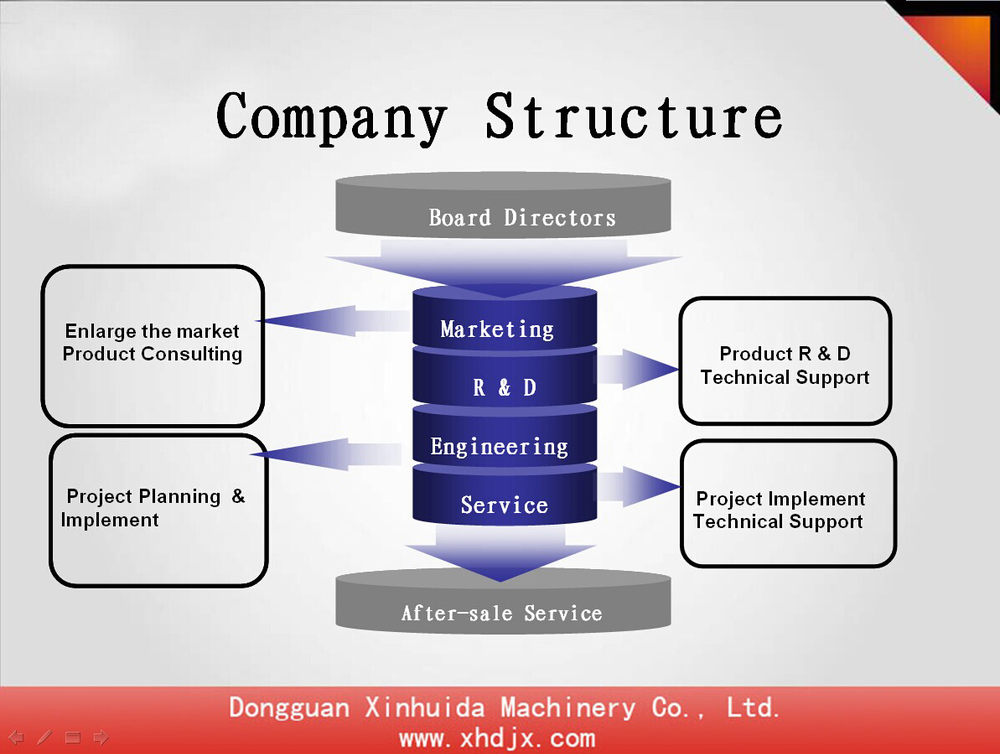

Company Information

XHD will be your best choice and suppiler for stretch film machine. We have very large after-sale service team and the technical support.

Packaging & Shipping

Machine Loading for Domestic and Oversea's Market

Packaging Condition of plastic injection moulding machine spare part

1) Packed fully with EPE foam, blanketry and stretch film.

2) Wire netting fastened at the bottom of the container.

Agent Wanted

Xinhuida will attend the exhibitions in different countries to help agent open the market. (Russia, Turkey, India, Egypt, Dubai, Chinapls...)

Our Services

1> One Year After Sale Service for FREE

2> Hot Line 400-833-5568 24 Hours Available

3> Technical Support and Installation Video Provided

4> Engineers is availble to the overseas

5> Free Trainning for Customer's Operator

5> High Quality Film Recipe Sharing

6> Problem Response within 12 huors

FAQ

Q: Can we make both manual grade and machine grade stretch film?

A: Yes.

Q: Can we make 5 layer stretch film by this machine?

A: Yes. You can make both 3 layer and 5 layer stretch film.

Q: Is this machine full automatic?

A: Yes. This machine is fully automatic one.

Q: Can we also use recycled material in this machine?

A: Yes. You can use recycled material. But the more recycled material you add, the stretch film will not as stretchable and transparency as the raw material one. One of our customer in Russia used 100% recycled material. Of course, the design of the screw will be a little different.

Q: What's the spare parts?

A: We have a lot of spare parts free to you. Pls email me for the list.

Q: Is there any other material that we use add to make stretch film?

A: It depends on your customers requiryment. You can add MLLDPE (metallocene) to make the film more stretchable, especially used in pallet package. Or the glue to make the film more sticky.

Q: Can you help us to install the machine?

A: Yes. We can arrange the technician to install the machine after it arrives in your factory.

Website : http://dgxinhuida.en.alibaba.com/

Welcome to our company and factory!

Search " Dongguan Xinhuida Machinery Co., Ltd" through YOUTUBE. Find More videos about how XHD stretch film machine performance.

Contact us if you need more details on Plastic Film Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pe Cling Film Machine、5 Layer Blown Film Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Three/Five Layers Stretch Film Machine > XHD-L65/90/65*1850 stretch/cling film machine