automatic 2000 mm pallet stretch film plastic tension film making machinery

| Delivery Time: | 60 Days |

|---|

| Packaging: | 1) plastic tension film making machinery is fully packed with PE stretch film and loaded in 2 40HQ containers. 2) Machine is fastened to the corners of the containers |

|---|---|

| Brand: | XHD |

| Place of Origin: | Guangdong, China (Mainland) |

Basic Info

Model No.: XHD-L 65/100/80X2350

Product Description

Films produced by plastic tension film making machinery

Films produced by plastic tension film making machinery  Parameters of plastic tension film making machinery

Parameters of plastic tension film making machinery No. | Item | Specs | Remarks |

1 | Voltage/Frequency/Phase | Customized | / |

2 | Total Installation Power | 220 KW | For the machine only. |

3 | Consumption Power | 160 KW | For the machine only. |

4 | Main Raw Material | LLDPE & MLLDPE | / |

5 | Thickness of Film | 10-50 μm | tolerance≤±5% |

6 | Width of the Useful Film | 2000 mm/4×500 mm | / |

7 | Film Layer Structure | ABC or ACBCA | ratio: 30%40%30% |

8 | Designed Linear Speed | 200 M/min | / |

9 | Output | 65-350 Kg/h | / |

10 | Dimensions (L×W×H) | 14×4.8×4.5 M | for ref. only |

11 | Gross Weight | 20000 Kg | for ref. only |

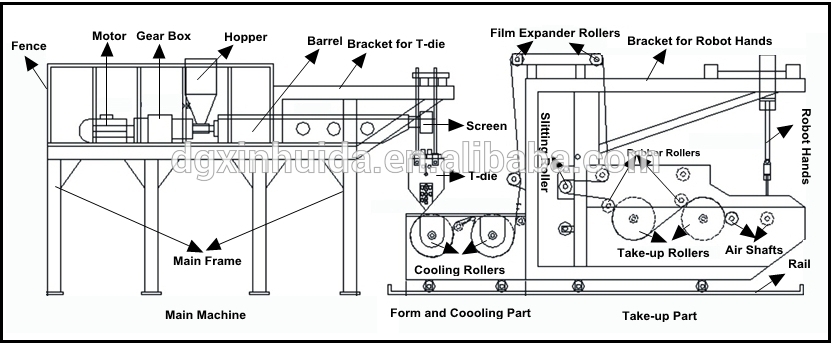

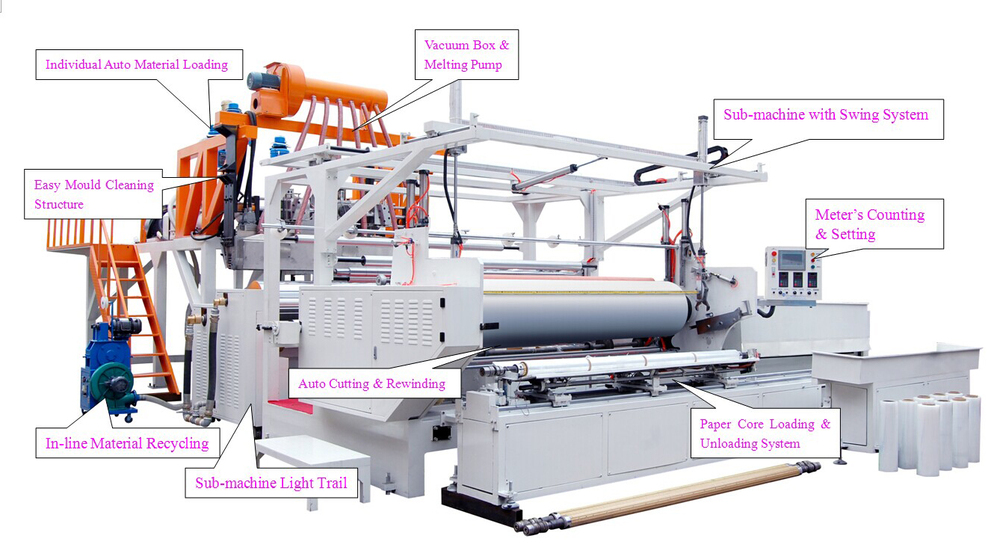

Main Components of plastic tension film making machinery

Main Components of plastic tension film making machinery  Features of plastic tension film making machinery 1. High output due to > high plasticization design alloy screws; > imported static mixer; > high quality T-die which is made of imported top quality mould steel. > high speed winding design

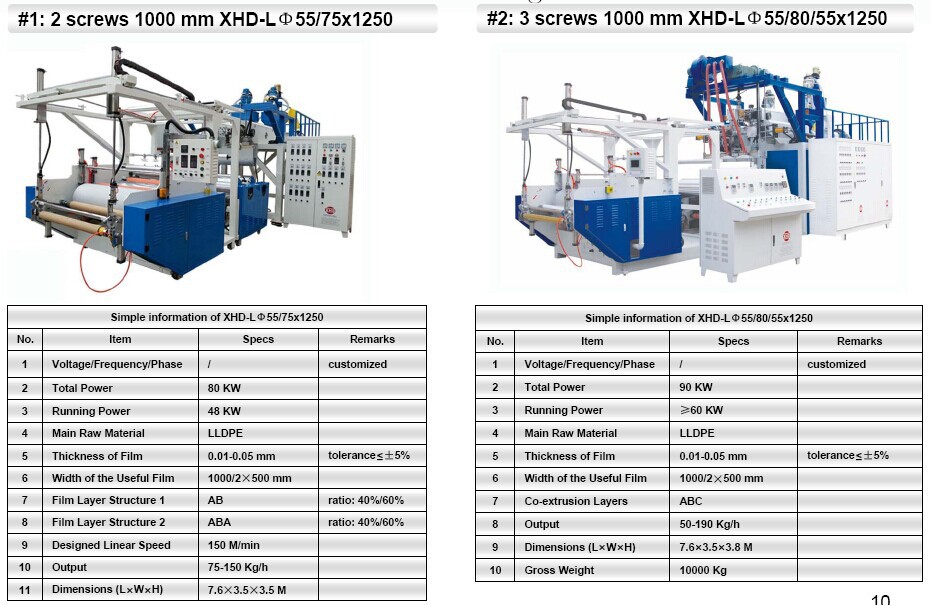

Features of plastic tension film making machinery 1. High output due to > high plasticization design alloy screws; > imported static mixer; > high quality T-die which is made of imported top quality mould steel. > high speed winding design Model | Max Running Speed | Maximum Output | Film Thickness |

XHD-LΦ 55/75-1250 | 100 M/min | 150 Kg/H | 0.02 mm |

XHD-LΦ 65/90/65-1850 | 120 M/min | 260 Kg/H | 0.02 mm |

XHD-LΦ65/100/80-2350 | 145 M/min | 310 Kg/H | 0.02 mm |

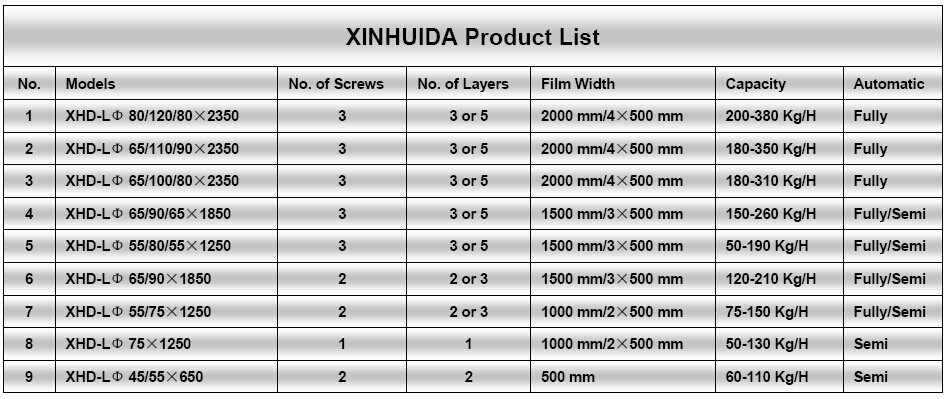

Four hot-selling plastic tension film making machinery

Four hot-selling plastic tension film making machinery

Auxiliary equipment

Auxiliary equipment  Packaging & Shipping Packing information for customer's reference >1. Packed with stretch film; >2. The machine is fastened to the walls of the container; >3. Dimensions: 12X3.6X3.4 M; >5. Gross weight: 15 T; >6. Containers needed: 1X40 HQ+1X20 GP. Pictures of loading plastic tension film making machinery

Packaging & Shipping Packing information for customer's reference >1. Packed with stretch film; >2. The machine is fastened to the walls of the container; >3. Dimensions: 12X3.6X3.4 M; >5. Gross weight: 15 T; >6. Containers needed: 1X40 HQ+1X20 GP. Pictures of loading plastic tension film making machinery

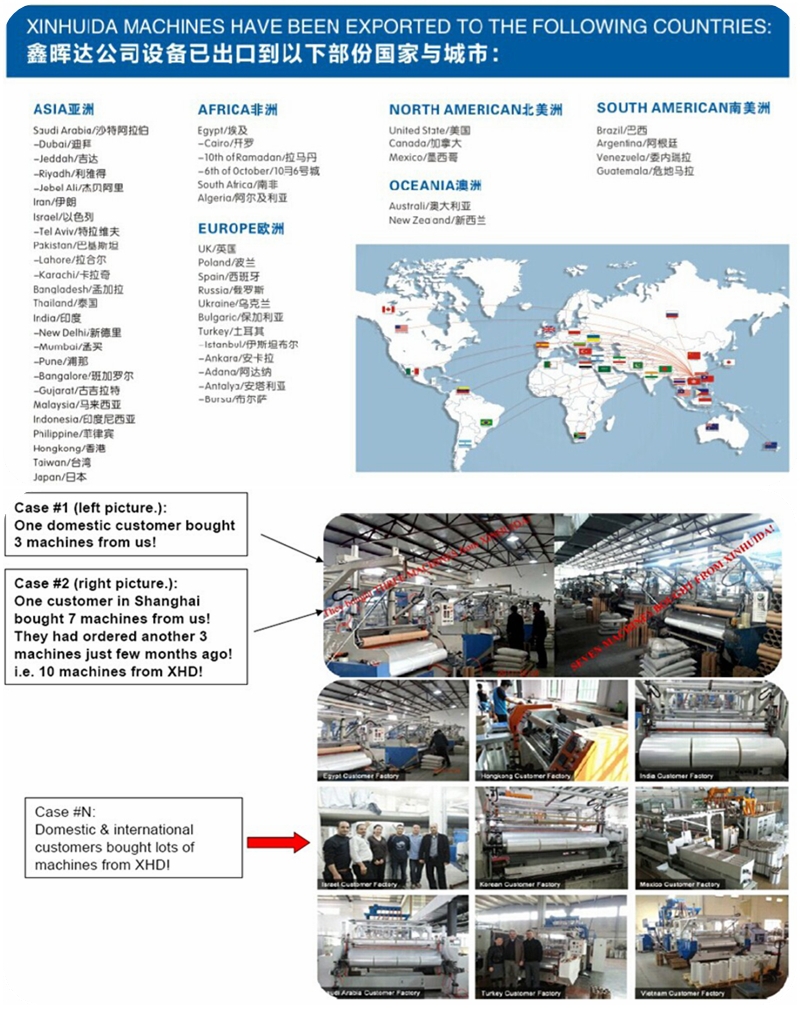

Customer cases XINHUIDA had sold plastic tension film making machinery all around the world. We can provide our customer information for your evaluation! You can even visit our customers' factories to check the machine running!

Our Services >1. 24 hours after-sale hot line 400-833-5568. >2. High quality stretch film recipe free sharing. >3. 1 year warranty for all system and free technology support. >4. Engineer dispatched to install the machine with travelling cost borne by the buyer. Company Information Established in 2000. With years’ experience in Stretch Film Making Machine & cling film making machine manufacturing. Avenue in 2014: around 60 million RMB (US$ 10 million) Domestic market share: 40% Exported machines to 50+ oversea cities No. of technicians: 30+ No. of sales team: 10 No. of after-sale service team: 10 Exhibitions and certificates

Our Services >1. 24 hours after-sale hot line 400-833-5568. >2. High quality stretch film recipe free sharing. >3. 1 year warranty for all system and free technology support. >4. Engineer dispatched to install the machine with travelling cost borne by the buyer. Company Information Established in 2000. With years’ experience in Stretch Film Making Machine & cling film making machine manufacturing. Avenue in 2014: around 60 million RMB (US$ 10 million) Domestic market share: 40% Exported machines to 50+ oversea cities No. of technicians: 30+ No. of sales team: 10 No. of after-sale service team: 10 Exhibitions and certificates  FAQs

FAQs>1. Q: Can your machine produce other kinds of film? A: Yes. Our machine also can produce: >silage film machine >2. Q: What's the thickness arrange of the film produced by your machine? A: For stretch film, the thickness is from 0.01mm to 0.05 mm; For cling film, the thickness is from 0.008 to 0.01 mm; For silage film, the thickness is from 0.012 to 0.05 mm; Please note, the thickness of silage film sold in the market is 0.015 to 0.035 mm. >3. Q: Can we customize some components of the machine? A: Yes. Most of our components are from China or worldwide famous suppliers. You don't have to worry about the replacement of broken parts or the after-sale service. >4. Q: When can you send the engineers for installation, debugging and training of our workers. A: It depends, but we usually arrange the engineers before the shipment. The buyer can have his machine running once he receive it. We also have some agents around the world to provide installation service or technical support. All traveling cost of the engineer the such as air tickets, food and shelter cost will be borne by the buyer. .... For more details about plastic tension film making machinery, please click and send inquiry to:

Contact us if you need more details on Plastic Tension Film Making Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Film Making Machinery、Tension Film Making Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Plastic Tension Film Making Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Film Making Machinery、Tension Film Making Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Three/Five Layers Stretch Film Machine > XHD-L65/100/80*2350 stretch/cling film machine