log roll slitting and rewinding machine

log roll slitting and rewinding machine

| Delivery Time: | 60 Days |

|---|

| Packaging: | 1) Packed fully with EPE foam, blanketry and stretch film. 2) Wire netting fastened at the bottom of the container. |

|---|---|

| Brand: | XHD |

| Place of Origin: | Guangdong, China (Mainland) |

Basic Info

Model No.: XHD-500

Product Description

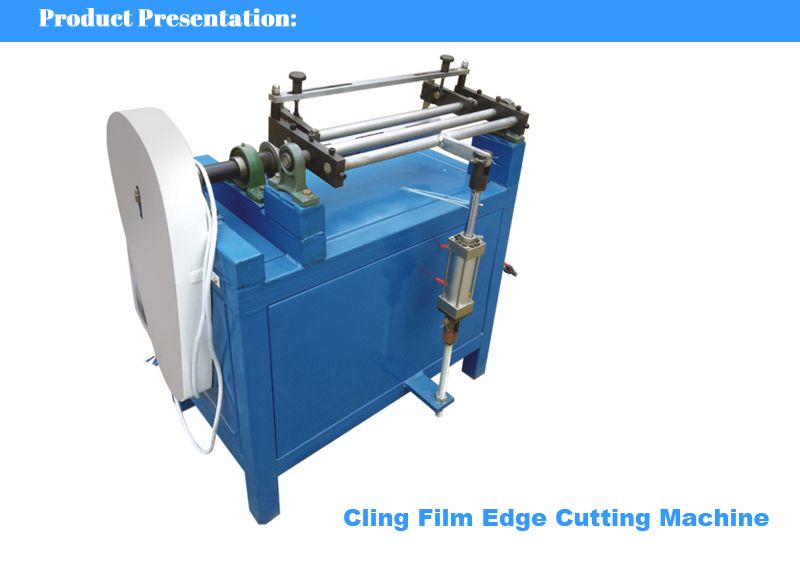

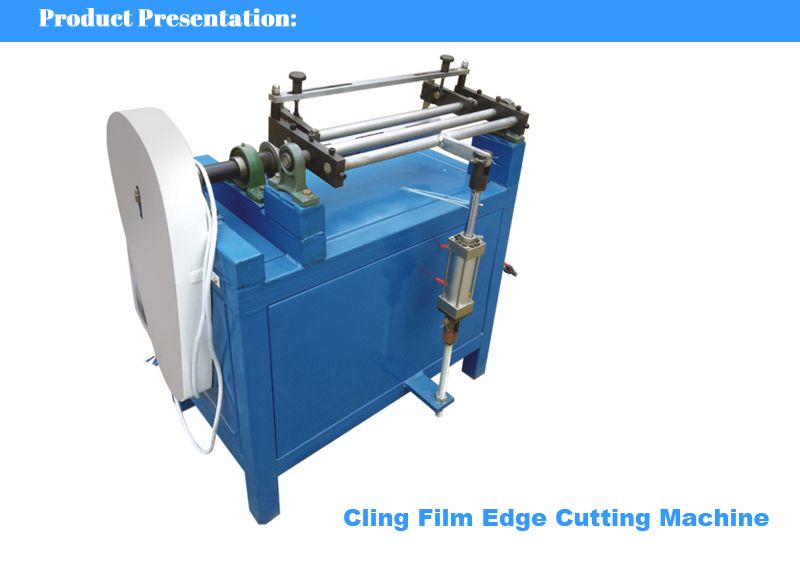

Specifications log roll slitting and Rewinding Machine

1.Stable running

2.Durable,hard steel made

3.ISO/SGS/CE/CCC

Product Description Details of log roll slitting and rewinding machine log roll slitting and rewinding machine is safe and easy to operate,it is make the winding material more even and soild.And the anti-puncture is better after contact with air.The unit is suitable for Stretch film,warpping film,casting film and preservative film to rewind.

Product Description Details of log roll slitting and rewinding machine log roll slitting and rewinding machine is safe and easy to operate,it is make the winding material more even and soild.And the anti-puncture is better after contact with air.The unit is suitable for Stretch film,warpping film,casting film and preservative film to rewind.

Detail Technical Parameter of log roll slitting and rewinding machine  Usage:it is mainly used to make the big diameter volumes into small ones,to correct the wrong-layer by rewind to improve the evenness of the winding material and appearance quality;the unit adopts flat belt transmission leak to make the load material speed the same with the leak speed.it is also reduce the production of srcondary membrane over-stretching,the friction pressure controlled by the cylinder.the units is convenient and flexible to adjust,small noise,frequency control,automatic meter winding,is the ideal cost performance winders.

Usage:it is mainly used to make the big diameter volumes into small ones,to correct the wrong-layer by rewind to improve the evenness of the winding material and appearance quality;the unit adopts flat belt transmission leak to make the load material speed the same with the leak speed.it is also reduce the production of srcondary membrane over-stretching,the friction pressure controlled by the cylinder.the units is convenient and flexible to adjust,small noise,frequency control,automatic meter winding,is the ideal cost performance winders.

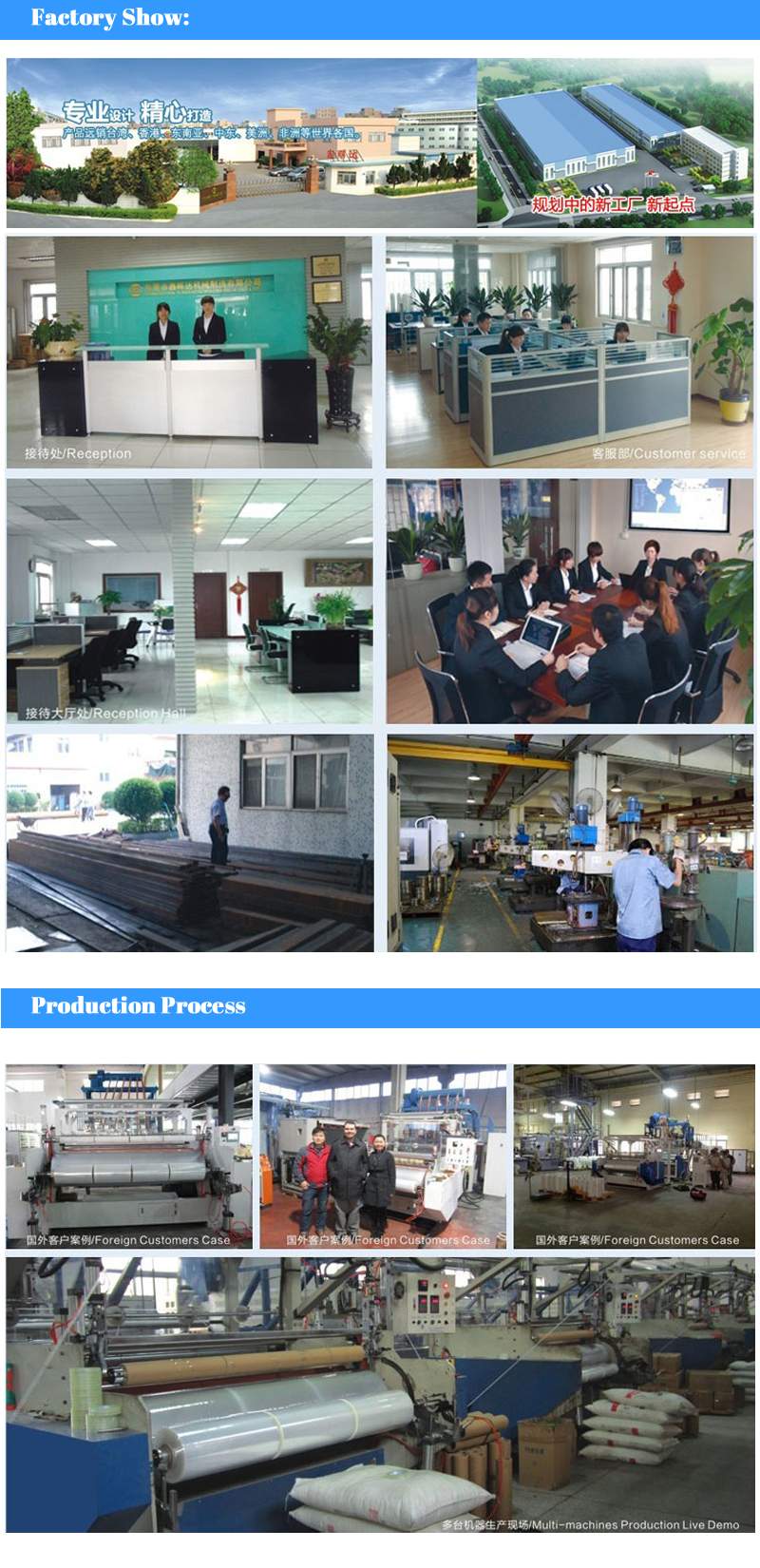

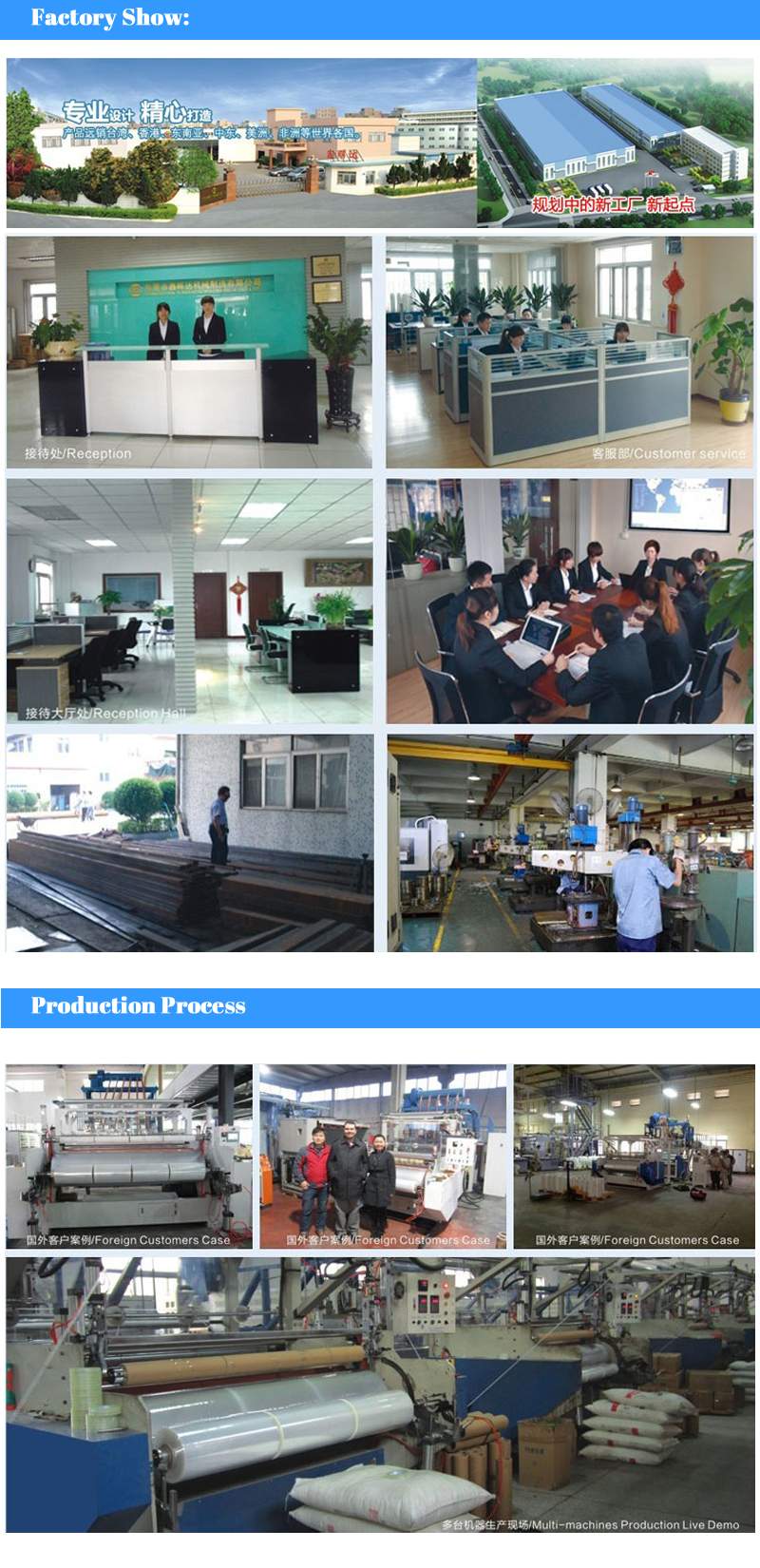

Company Information  Company Profile Dongguan Xinhuida Machinery Co.,Ltd is an enterprises established in 2000 which is specialized in log roll slitting and rewinding machine, the width from 500mm to 2000,single layer to multi layers. Our company is combined with machine design, R&D, manufacturing, sales and after sales services. We are honest and conscientious to supply our home and abroad customers with high quality, low power saving, high comparativer advance equipments. As the continuous professional technology and R&D introduced, now log roll slitting and rewinding machine have our own patent and trademark which all meet the ISO international certification. We are based on developing our advantage and combining our log roll slitting and rewinding machine features to provide our customers the high efficient machines to win market, leading the peer and building XINHUIDA professional brand which is praised by the global world. Under the pressure of the market economic trend and huge market competition, we keep innovating, seeking common ground while reserving. Packaging & Shipping

Company Profile Dongguan Xinhuida Machinery Co.,Ltd is an enterprises established in 2000 which is specialized in log roll slitting and rewinding machine, the width from 500mm to 2000,single layer to multi layers. Our company is combined with machine design, R&D, manufacturing, sales and after sales services. We are honest and conscientious to supply our home and abroad customers with high quality, low power saving, high comparativer advance equipments. As the continuous professional technology and R&D introduced, now log roll slitting and rewinding machine have our own patent and trademark which all meet the ISO international certification. We are based on developing our advantage and combining our log roll slitting and rewinding machine features to provide our customers the high efficient machines to win market, leading the peer and building XINHUIDA professional brand which is praised by the global world. Under the pressure of the market economic trend and huge market competition, we keep innovating, seeking common ground while reserving. Packaging & Shipping  Packaging Condition of log roll slitting and rewinding machine 1) Packed fully with EPE foam, blanketry and stretch film. 2) Wire netting fastened at the bottom of the container.

Packaging Condition of log roll slitting and rewinding machine 1) Packed fully with EPE foam, blanketry and stretch film. 2) Wire netting fastened at the bottom of the container.  FAQ Why did you choose us ? Xinhuida always hold the faith of high quality ,honesty , refinement, and innovation ,providing our customers best services and products . Our products are sold all over the world .Many customers are think highly of us and give good reputation . Don't hesitate .We are waitting for u ! Our Services

FAQ Why did you choose us ? Xinhuida always hold the faith of high quality ,honesty , refinement, and innovation ,providing our customers best services and products . Our products are sold all over the world .Many customers are think highly of us and give good reputation . Don't hesitate .We are waitting for u ! Our Services  Website : http://dgxinhuida.en.alibaba.com/ Welcome to our company and factory! Contact us if you need more details on Log Roll Slitting and Rewinding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rewinding Machine、Strip Slitting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Website : http://dgxinhuida.en.alibaba.com/ Welcome to our company and factory! Contact us if you need more details on Log Roll Slitting and Rewinding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rewinding Machine、Strip Slitting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Stable running

2.Durable,hard steel made

3.ISO/SGS/CE/CCC

Product Description Details of log roll slitting and rewinding machine log roll slitting and rewinding machine is safe and easy to operate,it is make the winding material more even and soild.And the anti-puncture is better after contact with air.The unit is suitable for Stretch film,warpping film,casting film and preservative film to rewind.

Product Description Details of log roll slitting and rewinding machine log roll slitting and rewinding machine is safe and easy to operate,it is make the winding material more even and soild.And the anti-puncture is better after contact with air.The unit is suitable for Stretch film,warpping film,casting film and preservative film to rewind. Model | XHD-500 |

Rewinder machine parent roll wideth | 300-500mm |

Main Motor Power | 2.2KW |

And move around motor | 0.37KW |

Mechanical wire-speed(max) | 200-600m/min |

Roll Type | Artificial roll |

Mother curly core specifications | 3' |

Mandrel size Sub-Volume | 3',2', Φ30mm |

Overall dimension(L*W*H) | 1.4m*1.0m*1.1m |

Weight | 580kg |

Usage:it is mainly used to make the big diameter volumes into small ones,to correct the wrong-layer by rewind to improve the evenness of the winding material and appearance quality;the unit adopts flat belt transmission leak to make the load material speed the same with the leak speed.it is also reduce the production of srcondary membrane over-stretching,the friction pressure controlled by the cylinder.the units is convenient and flexible to adjust,small noise,frequency control,automatic meter winding,is the ideal cost performance winders.

Usage:it is mainly used to make the big diameter volumes into small ones,to correct the wrong-layer by rewind to improve the evenness of the winding material and appearance quality;the unit adopts flat belt transmission leak to make the load material speed the same with the leak speed.it is also reduce the production of srcondary membrane over-stretching,the friction pressure controlled by the cylinder.the units is convenient and flexible to adjust,small noise,frequency control,automatic meter winding,is the ideal cost performance winders.

| Windmil Motor | HP | 2 |

| Workload | Kgs/hr | 15-60 |

| Cyclone diameter | mm Φ | 250 |

| L*W*X | mm | 1000*500*850 |

| Packing size | m | 1.2*1.1*0.9 |

| Weight | kgs | 280 |

| Capacity of Barrel | HR-150 | HR-300 | HR-500 |

| Production capacity | 60-80kg/h | 200-300kg/h | 400-500kg/h |

| Main motor power | 18.5kw | 37w | 75-90kw |

| Water Adding Device | 90w | 90w | 90kw |

| speed of mainshaft | 660r/min | 660r/min | 660r/min |

| Total Weight | 900kg | 1200kg | 1500kg |

| Dimension(mm) | 1600*800*1600 | 2000*900*1700 | 2200*1000*1700 |

| Parts Name | Unit | parameters |

| Mashing Motor | H | P2 |

| Turning diameter | mm Φ | 180 |

| Knife length | mm | 163 |

| Number of fixed knives | Pcs/set | t2 |

| The number of rotary knife | Pcs/set | 3 |

| Mesh aperture | mm Φ | 3-5 |

| Model | XHD-500 |

| Width of finished product(mm) | 500 |

| Power of motor(kw) | 4 |

| Liner speed of machinery(m/min) | 1000 |

| Roll Lay Mode(mm) | Automatic |

| Diameter of parent roll(max)(mm) | 500 |

| Width of parent roll(max)(mm) | 500 |

| Core specification of parent roll | 3'' |

| Cutting mode | by resistance wire |

| Width of sub-roll(max)(mm) | 300/350/400/450/500 |

| Diameter of sub-roll | 200 |

| Core specification of sub-roll | 3''2'' |

| Overall dimensions(m) | 2.6*1.8*1.4 |

| Weight | 0.8 |

Company Profile Dongguan Xinhuida Machinery Co.,Ltd is an enterprises established in 2000 which is specialized in log roll slitting and rewinding machine, the width from 500mm to 2000,single layer to multi layers. Our company is combined with machine design, R&D, manufacturing, sales and after sales services. We are honest and conscientious to supply our home and abroad customers with high quality, low power saving, high comparativer advance equipments. As the continuous professional technology and R&D introduced, now log roll slitting and rewinding machine have our own patent and trademark which all meet the ISO international certification. We are based on developing our advantage and combining our log roll slitting and rewinding machine features to provide our customers the high efficient machines to win market, leading the peer and building XINHUIDA professional brand which is praised by the global world. Under the pressure of the market economic trend and huge market competition, we keep innovating, seeking common ground while reserving. Packaging & Shipping

Company Profile Dongguan Xinhuida Machinery Co.,Ltd is an enterprises established in 2000 which is specialized in log roll slitting and rewinding machine, the width from 500mm to 2000,single layer to multi layers. Our company is combined with machine design, R&D, manufacturing, sales and after sales services. We are honest and conscientious to supply our home and abroad customers with high quality, low power saving, high comparativer advance equipments. As the continuous professional technology and R&D introduced, now log roll slitting and rewinding machine have our own patent and trademark which all meet the ISO international certification. We are based on developing our advantage and combining our log roll slitting and rewinding machine features to provide our customers the high efficient machines to win market, leading the peer and building XINHUIDA professional brand which is praised by the global world. Under the pressure of the market economic trend and huge market competition, we keep innovating, seeking common ground while reserving. Packaging & Shipping  Packaging Condition of log roll slitting and rewinding machine 1) Packed fully with EPE foam, blanketry and stretch film. 2) Wire netting fastened at the bottom of the container.

Packaging Condition of log roll slitting and rewinding machine 1) Packed fully with EPE foam, blanketry and stretch film. 2) Wire netting fastened at the bottom of the container.  FAQ Why did you choose us ? Xinhuida always hold the faith of high quality ,honesty , refinement, and innovation ,providing our customers best services and products . Our products are sold all over the world .Many customers are think highly of us and give good reputation . Don't hesitate .We are waitting for u ! Our Services

FAQ Why did you choose us ? Xinhuida always hold the faith of high quality ,honesty , refinement, and innovation ,providing our customers best services and products . Our products are sold all over the world .Many customers are think highly of us and give good reputation . Don't hesitate .We are waitting for u ! Our Services  Website : http://dgxinhuida.en.alibaba.com/ Welcome to our company and factory! Contact us if you need more details on Log Roll Slitting and Rewinding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rewinding Machine、Strip Slitting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Website : http://dgxinhuida.en.alibaba.com/ Welcome to our company and factory! Contact us if you need more details on Log Roll Slitting and Rewinding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rewinding Machine、Strip Slitting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Semi-auto Slitter and Rewinder

Other Products

Hot Products

China Professional Manufacture Automatic Food Wax /Silicon/PE Paper/House Foil RewinderStretch Film Rewinding Slitter CE (FTRW-500)Fts-500 Auto PE Stretch Film Rewinding Machine (CE)Sjpp Model PP Film Blowing Machine (CE)Rotary Head Film Blowing Machine (CE)Double Layer Stretch Film Making Machine Ce (FT-500)Air Bubble Film Making Machine Ce (FTPE-1200)5 layer co extruded plastic stretch film machineryThree layer pe cast stretch film making machineDouble layer co extrusion stretch film production lineHigh speed 3 layers or 5 layers stretch film machinery/XHD-L65/100/80-2350 Supplier's ChoiceNew condition and film application PE stretch film extrusion machineFilm Rewinding and Slitting Machine, Stretch Film Rewinding MachineAuto Film Rewinder Machinery, Full Auto Film Rewinding MachineFive Layer Stretch Film Machine, Stretch Film Producing MachineDouble Layer Stretch Film Machine